Description

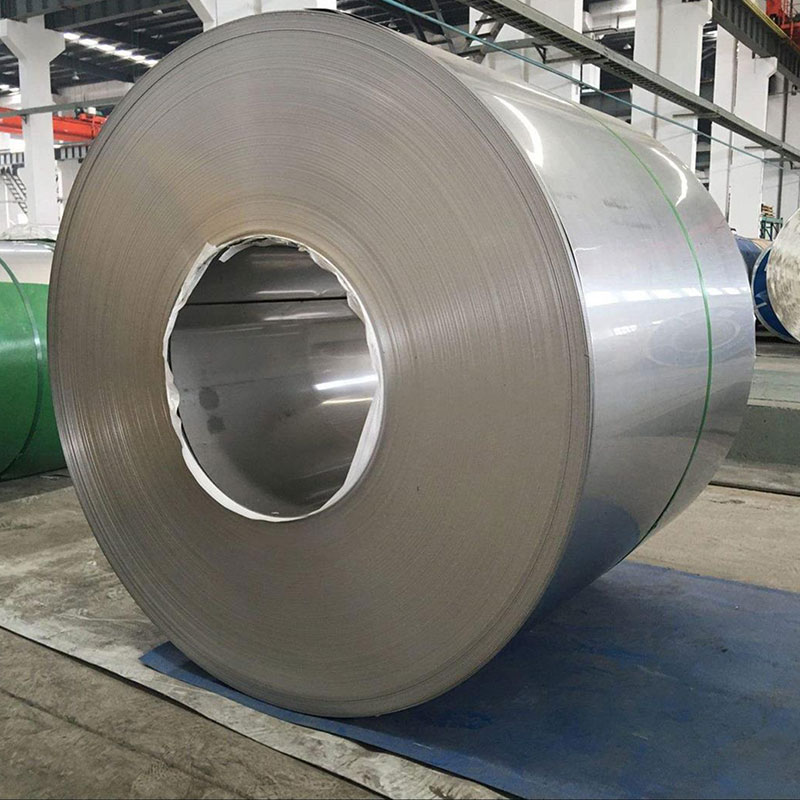

316L / 1.4404 Stainless Steel Coil

China’s uniform digital code for S31603, the standard grade for 022CR17NI12MO2 (new standard), the old grade for 00CR17NI14MO2, said it mainly contains Cr, Ni, Mo, the number says it probably contains a percentage.316L has a wide range of applications in the chemical industry because of its excellent corrosion resistance. 316L is also a derivative of 18-8 austenitic stainless steel, with 2 ~ 3% Mo element added.

On the basis of 316L, many kinds of steel are also derived. For example, 316Ti is derived after adding a small amount of Ti, 316N is derived after adding a small amount of N, and 317L is derived by increasing the content of Ni and Mo.

Most of the existing 316L in the market are produced according to American standards.

For cost consideration, steel mills generally put the Ni content of products as far as possible by the lower limit.

The American standard stipulates that the Ni content of 316L is 10 ~ 14%, while the Japanese standard stipulates that the Ni content of 316L is 12 ~ 15%.

According to the minimum standard, there is a 2% difference between the American standard and Japanese standard in the Ni content, which is still quite huge in the price. Therefore, customers still need to see clearly when buying 316L products, whether the products refer to ASTM or JIS standards.

The Mo content of 316L makes the steel have excellent pitting resistance and can be safely used in environments containing Cl- and other halogen ions.

Because 316L is mainly used for its chemical properties, steel mills have slightly lower requirements for surface inspection of 316L (relative to 304), and customers with higher surface requirements should strengthen surface inspection.The most commonly used two kinds of stainless steel 304,316 (or corresponding to the German/European standard 1.4308,1.4408), 316 and 304 in the chemical composition of the most important difference is that 316 contains Mo, and generally recognized, 316 corrosion resistance is better, more corrosion resistance than 304 in high temperature environment.

Therefore, in the high temperature environment, engineers generally choose parts made of 316 materials.

But the so-called thing is not absolute, in the concentrated sulfuric acid environment, then the high temperature also do not use 316. Otherwise, this matter can be a big.

Mechanical people have learned the thread, remember in order to prevent the thread in the high temperature, the need to apply a black solid lubricant: molybdenum disulfide (MoS2), from which can draw 2 conclusions: one: Mo is indeed a kind of high temperature resistant material (know what crucible gold melting?

Molybdenum crucible!)Two: molybdenum is easy to react with high sulfur ions to produce sulfide.

So no stainless steel is super corrosion-resistant.

In the final analysis, stainless steel is a piece of impurities (but these impurities can be more corrosion resistant than steel) more steel, steel can react with other substances.

Equivalent Material of 316L Stainless Steel Coil

| China * GB | GB24511 | 022Cr17Ni12Mo2 |

| Japan | JIS | SUS316L |

| United States of America | ASTM | 316L |

| UNS | S31603 | |

| South Korea | KS | STS316L |

| European Union | BSEN | 1.4404 |

| India | IS | ~02Cr17Ni12Mo2 |

| Australia | AS | 316L |

| Taiwan, China | CNS | 316L |

| Germany | DIN | X2CrNiMo17-12-2 |

| United Kingdom | BS970 BS1449 | 316S12 |

| Belgium | BS970Part1 | – |

Standard Specification Of 316L coil

Thickness 0.3mm-12.0mm

Width 600mm, 700mm, 800mm, 900mm, 1000mm, 1200mm, 1220mm, 1500mm, etc

Length Per Coil

Surface 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc

Finish Cold rolled coil (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Form Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats,

Blank (Circle), Ring (Flange) etc.

316L stainless steel composition content.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316L | Min. Max. |

≤0.03 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.03 | 16.00~18.00 | 2.00~3.00 | 10.00~14.00 | |

Tensile strength σb (MPa) : ≥480

Conditional yield strength σ0.2 (MPa) : ≥177

Elongation Δ5 (%) : ≥40

Section shrinkage ψ(%) : ≥60

Hardness: 187 hb or less;

90 HRB or less;

200 hv or less

Density: 7.98g/cm3;

Specific heat capacity ratio (20℃) : 0.502J/(g*K)

Contact Us Now!

If you need product information or price, please fill in your contact information in the form below, we will usually contact you within 12 hours. You could also email me info@sinosteel.ltd to get prompt reply.

Send me the inquiry,free samples and the most favorable quotation are waiting for you!

Supply Better Material for Project & Find Best Solution for Clients

Wish your business boom and all the best!