Description

316 / 1.4401 Stainless Steel Sheet

316 stainless steel contains Mo, and it is generally recognized that 316 has better corrosion resistance and is more resistant to corrosion in high temperature environments than 304.

Equivalent Material of 316 Stainless Steel Sheet

| China * GB | GB24511 | 06Cr17Ni12Mo2 |

| Japan | JIS | SUS316 |

| United States of America | ASTM | 316 |

| UNS | S31600 | |

| South Korea | KS | STS316 |

| European Union | BSEN | 1.4401 |

| India | IS | 04Cr17Ni12Mo2 |

| Australia | AS | 316 |

| Taiwan, China | CNS | 316 |

| Germany | DIN | X5CrNiMo17-12-2 |

| United Kingdom | BS970 BS1449 | 316S16 |

| Belgium | BS970Part1 | 316S31 |

Standard Specification Of 316 Plate

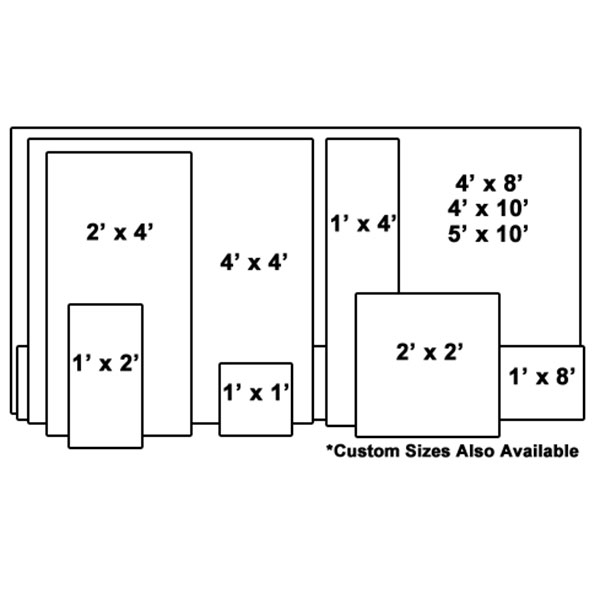

| Thickness | 0.25mm-100mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

316 stainless steel Usage

Because of its excellent corrosion resistance, it has a wide range of applications in the chemical industry. Its characteristics are plasticity, toughness, cold denaturation, and good welding process performance. Because of its low carbon content and 2%-3% molybdenum, it has improved Corrosion resistance of reducing salts and various inorganic and organic acids, alkalis, salts, and high temperature strength.

The main uses are heat exchangers for pulp and papermaking equipment, dyeing equipment, film washing equipment, pipelines, and external materials for buildings in coastal areas. It is also used in the field of solenoid valves, the main answer is to be used for housing, clamp, ball, valve body, valve seat, nut, valve stem, etc.

What is the difference between 316 and 316L?

1. Different ingredients

316L is ultra-low carbon, and L stands for low carbon, so the carbon content of 316L is lower than that of 316.

316 chemical composition C (carbon) ≤0.08, 316L chemical composition (%): C (carbon) ≤0.03

2. Different corrosion resistance

316L stainless steel has better resistance to intergranular corrosion and better anti-corrosion and anti-rust ability.

3. Different intensity

The strength of 316L material is lower than that of 316, which is convenient for processing.

Yield strength: 316 material is 210 (N/MM2), 316L material is 180 (N/MM2).

Tensile strength: 316 material is 520 (N/MM2), 316L material is 480 (N/MM2)

4. Different welding methods

The welded section of 316 stainless steel requires post-weld annealing treatment, while 316L stainless steel does not.

5. There are differences in grades

316 grade: the old grade is 0Cr17Ni12Mo2, and the new grade is 06C17N12M2, which is the American standard TP316 and the Japanese standard SUS316.

316L grade: The old grade is 00Cr17Ni14Mo2, and the grade is 022C17N12M2, which is the standard TP316L and the Japanese standard SUS316L.

6. Heat resistance

316 material can be used intermittently below 1600 degrees and continuous use below 1700 degrees, but it is best not to use 316 stainless steel in the range of 800-1575 degrees.

316L stainless steel has better resistance to carbide precipitation than 316 stainless steel, and it can also be used in the temperature range of 800-1575 degrees.

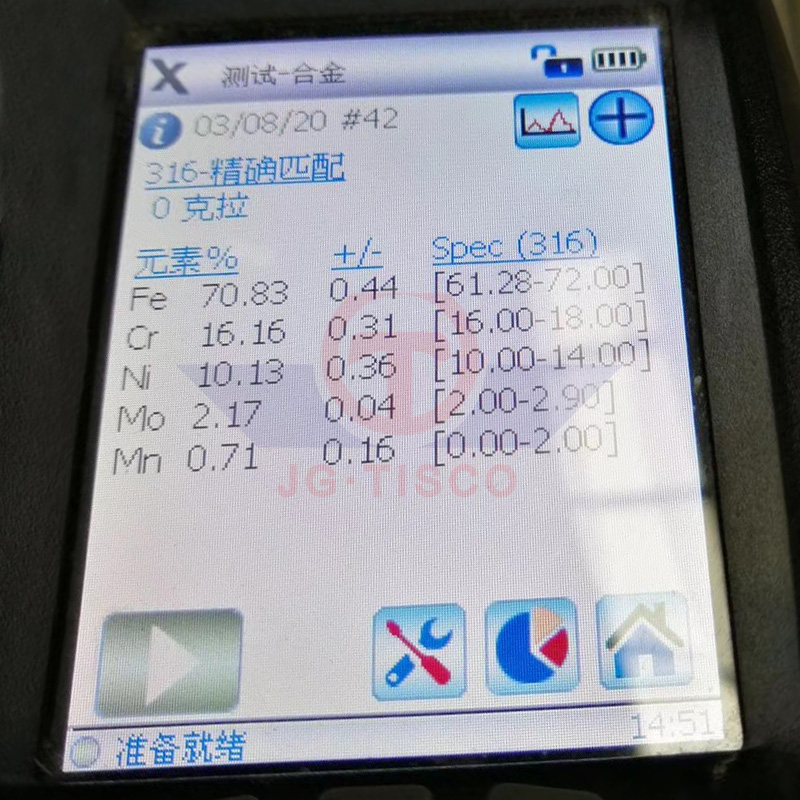

316 stainless steel composition content.

| Grade | 316Min.-Max. |

| C | ≤0.08 |

| Mn | ≤2.00 |

| Si | ≤1.00 |

| PS | ≤0.035 |

| Cr | ≤0.03 |

| Mo | 16.0-18.5 |

| Ni | 2.0-3.0 |

| N | 10.0-14.0 |

The tensile strength (MPa) was 620 MIN

The yield strength (MPa) was 310 MIN

Elongation rate (%) 30 MIN

Area reduction (%) 40 MIN

Contact Us Now!

Our products: stainless steel including all sizes of steel coils, steel sheets, steel pipes, flat steel, angle steel, round steel, channel steel and other metal materials.

If you need product information or price, please fill in your contact information in the form below, we will usually contact you within 12 hours. You can also click on our email address info@sinosteel.ltd to send us an email to get prompt reply.

Send me the inquiry,free samples and the most favorable quotation are waiting for you!

Supply Better Material for Project & Find Best Solution for Clients

Wish your business boom and all the best!