PQF continuous roll stand realizes localization

The PQF continuous rolling mill is the key equipment of the hot-rolled seamless steel pipe production line. When producing small batches, multiple specifications, and multiple varieties of steel pipes, it is equipped with a certain number of offline standby roll stands (movements), which can greatly shorten the waiting time for equipment adjustment. Improve productivity. For a long time, due to the high precision requirements of the roll movement and the complex processing technology, it is the core component of the unit. In order to ensure the accuracy and reliability of the entire unit, we have always used the original imported German movement in project execution, but the imported parts are relatively expensive. Cost and long delivery time are hard to ignore disadvantages for customers. In recent years, there are also other domestic manufacturers in the market that make domestically produced similar products, but the use effect is not ideal, and there is a certain gap between the actual accuracy and the original design requirements after going online. Based on the concept of “in China, for China” and the principle of customer benefit first, SMS Siemag decided to make the roll movement domestically produced on the basis of ensuring the same quality as the original design, and realize “German craftsmanship, made in China” locally.

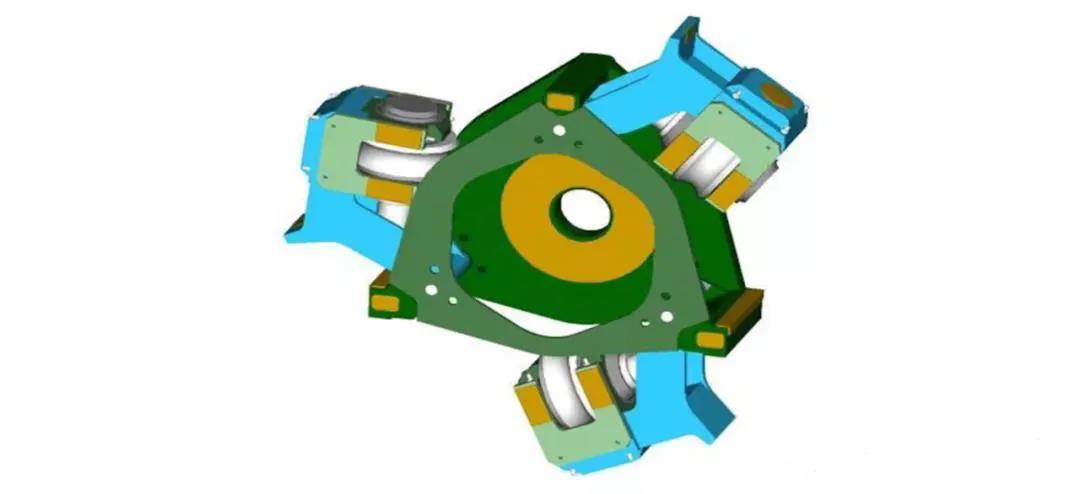

The structure of the PQF roll movement is a pin-swing rod system developed by SMS. This system controls the roll stand through the high-pressure cylinder of the hydraulic servo small warehouse, so as to control and adjust the roll gap in real time to make the wall thickness of the rolled steel pipe It can meet the higher technological requirements and effectively avoid the disadvantages of unstable accuracy during rapid roll change. However, due to the asymmetry and complexity of the frame structure, to fully guarantee its high-precision requirements, there are no small challenges in every link of domestic production. SMS China first screened and judged its feasibility and the difficulties that may be encountered in the manufacturing process, and recorded the processing difficulties in detail, and then strived to break them one by one during the implementation of localization to ensure the production of the roll movement. Foolproof, so as to protect the interests of customers. In 2019, SMS and a well-known domestic steel company signed a contract for the supply of 460PQF roll movement. The four sets of domestic-made roll movements completely follow the original design drawings, adopt SMS processing technology and technology, and strictly control the quality in accordance with SMS SN200 standards, and each production checkpoint is successfully manufactured with a meticulous and refined attitude. A domestic movement with high precision requirements. The four sets of movements have been running smoothly since they were delivered to use, without any quality problems, and have been highly praised by customers. Based on the trust in SMS, the customer renewed 10 sets of roll movements in its 241 pass modification project.