Seawater is highly corrosive, and equipment that has been immersed in seawater for a long time in particular should have anti-corrosion properties. Here, the superiority of stainless steel in terms of corrosion resistance is clear.

Propellers

Propellers on all types of vessels can be made from cast stainless steel CF-8 (equivalent to dry type 304 stainless steel). Recent developments in stainless steel technology have seen the use of complex austenitic-ferritic stainless steel 20Cr-8Ni-3.5Mo to cast large propellers (weighing up to 3000kg) on ocean-going vessels.

Ships often working in port are particularly prone to encounter logs or other floating bodies on the sea and accelerate the damage to the propellers. Therefore, thrusters made of austenitic stainless steel can be repaired by straightening or welding.

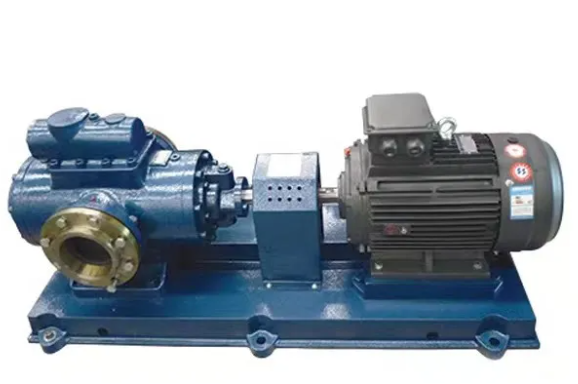

Centrifuge

It has long been observed that centrifugal pumps work in seawater conditions, such as the use of stainless steel components, can show a certain degree of reliability.

In maintaining the flow of seawater, the use of CF-8M cast stainless steel impellers (whose composition is equivalent to type 316 stainless steel) and the use of type 316 stainless steel for the main shaft can be used without any problems. Crevice corrosion and pitting corrosion are likely to become serious problems when the pump stops working.

But if you come to use the more active and rust-prone cast iron manufacturing a wall thickness of a fairly large pump box, cast iron in downtime can play a cathodic protection.

When the pump work, cast iron box of cathodic protection under the role must be able to make under the stainless steel polarization, but the flow of water to maintain the cathodic protection role.

In addition, the long-term work of the pump may be due to alternate use, both when seawater is replaced with fresh water and play a protective role.

Stainless steel has been used as a bulk bag container in freight, for liquefied natural gas (LNG), chemicals, beverages, etc.

It is customary to use type 304L stainless steel for LNG containers in freight transport, not for corrosion resistance but for mechanical properties at low temperatures.